Key Properties of Plastic Materials

There are a wide variety of plastic materials, and common engineering plastics include ABS, POM, PMMA, PVC, nylon, PC, PEEK, and others. Their common properties include:

Lightweight: Plastics have a lower density and weigh less compared to metallic materials, making them suitable for projects where weight reduction is a requirement, such as aerospace and automotive.

- Chemical resistance: Most plastic materials have excellent chemical resistance and can be used for long periods of time in environments such as acids, alkalis and salts.

- Abrasion and impact resistance: Some plastics (e.g., nylon, POM) have good abrasion resistance and toughness, and can withstand high mechanical stress.

- Ease of processing: Plastic materials are easier to CNC process than metal, and can realize high-precision manufacturing of complex shapes, while processing costs are relatively low.

Application areas of plastic materials

Plastic materials have a wide range of applications, covering a number of demanding industries. The following are some typical applications:

- Electronic equipment: ABS and PC materials are commonly used in the manufacture of cell phone housings, laptop computer housings, keyboards and other electronic equipment components, because of their excellent electrical insulation and impact resistance.

- Automotive manufacturing: Nylon and POM are widely used in automotive parts, including gears, bearings, pulleys, etc., because of their high strength and wear resistance, which can extend the service life.

- Medical Devices: As a biocompatible material, PEEK is used in the manufacture of surgical instruments, implants, etc. It has high temperature resistance, chemical resistance and low coefficient of friction.

- Industrial machinery and equipment: PVC materials are commonly used in pipes, industrial equipment shells, etc., because of its low cost, high corrosion resistance and easy processing.

CNC machining in the performance of plastic materials

In CNC machining, plastic materials show the following advantages:

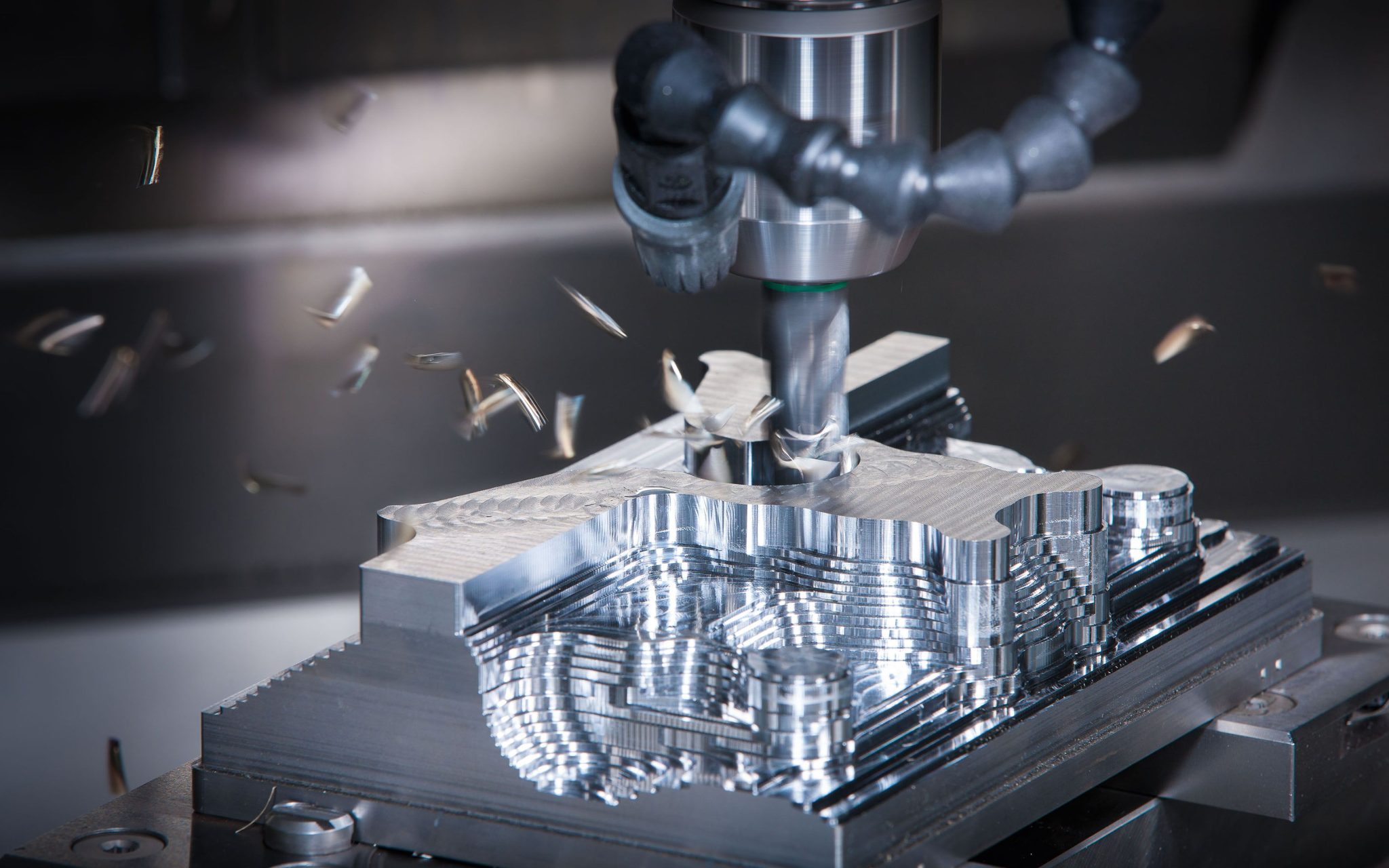

- High-precision manufacturing: CNC machining is able to cut plastic materials with micron-level precision, which makes it particularly suitable for the manufacture of complex components and demanding form designs. The relative softness of plastic materials also makes them less likely to damage tools during machining, reducing wear and tear during machining.

- Low-cost production: Plastic materials are less expensive than metal materials and offer faster machining speeds in CNC machining, reducing overall manufacturing costs and making them particularly suitable for small batch customized production.

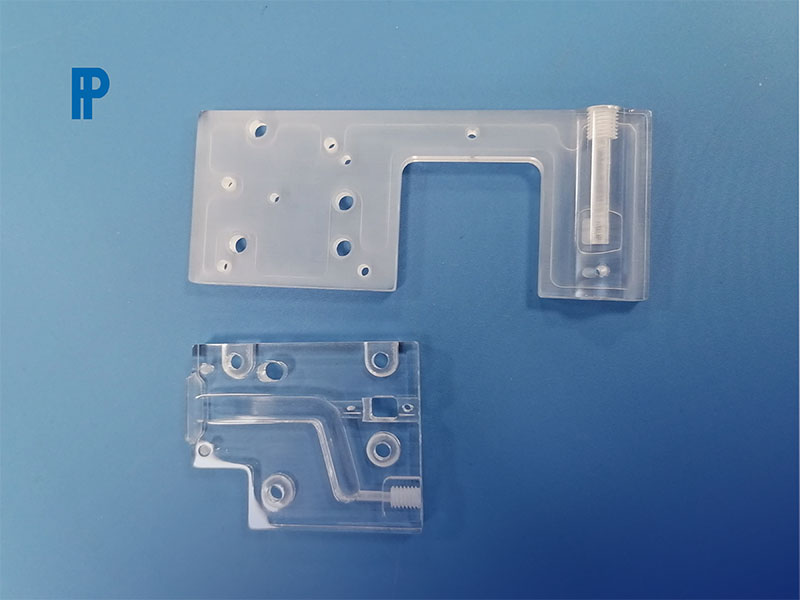

- Wide range of material options: Plastic materials come in a wide variety, each with unique physical and chemical properties. For example, ABS has excellent toughness and moldability, while PC has high transparency and impact resistance, making it suitable for shields and lens components.

Data and Case Studies

According to a market survey, global market demand for engineering plastics is growing rapidly, especially in the electronics and automotive manufacturing industries. In the case of nylon, for example, the global market for nylon materials was valued at approximately $27 billion in 2019 and is expected to reach $45 billion by 2026. In an automotive parts project served by FastPreci, we helped the customer use nylon materials to make high-precision gears, which not only reduced machining costs, but also significantly improved the wear resistance of the parts and extended the life of the equipment.

The performance of plastic materials in CNC machining is not only due to their ease of machining and high efficiency and low cost, but also to their ability to meet the high precision and performance requirements of a wide range of applications. From consumer electronics to automotive manufacturing and even medical devices, plastics are changing the way manufacturing is designed and produced, and FastPreci, a leader in CNC machining, offers a wide range of plastic material options to support customers from design through production. Choose FastPreci for the highest quality plastic material solution for your project.