Introduction to CNC Machining Equipment Types

CNC (Computer Numerical Control) machining equipment is a machine tool system that is automatically controlled by a computer program. Their core strengths lie in their high accuracy, efficiency and repeatability, and they are widely used in a variety of industries, including aerospace, automotive manufacturing, electronics, and medical. The following are common types of CNC machining equipment:

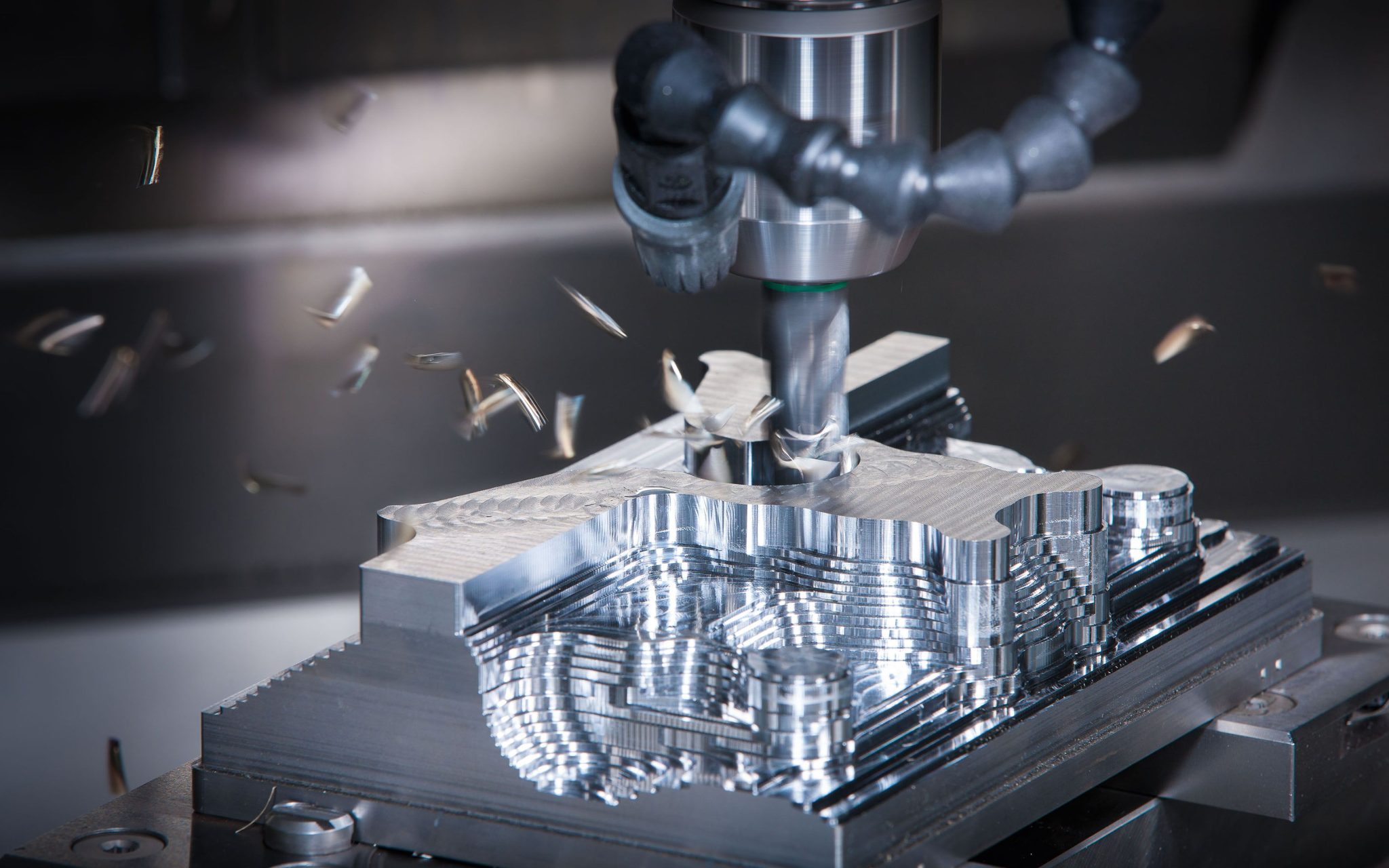

1. CNC Milling Machine

CNC milling machines are one of the most commonly used machines for everything from simple flat surface machining to complex three-dimensional modeling machining. They are characterized by their ability to accurately cut and grind a wide range of metal and plastic materials.

Application example: For example, when FastPreci custom produced complex shaped aluminum parts for an automotive parts manufacturer, the CNC milling machine achieved high-precision cutting with its 5-axis function, ensuring the accuracy of each part.

Processing capability data: The 5-axis CNC milling machine we use can achieve a machining accuracy of ±0.01mm, which is capable of meeting the stringent requirements of precision industrial parts.

2. CNC Lathe

CNC lathes are used for the machining of cylindrical parts and are particularly suitable for the manufacture of shafts, rings and other rotationally symmetrical parts. They are machined by rotating the workpiece and using cutting tools.

Application example: FastPreci helped a medical device company machine a stainless steel shaft component, utilizing the high-precision turning capabilities of the CNC lathe to ensure a surface finish of Ra0.8.

Equipment Data: Our CNC lathes can machine up to 300mm in diameter, and are capable of handling complex shaft parts in a wide range of sizes.

3. CNC Electro Discharge Machining (EDM)

EDM is used to process hard materials that are difficult to deal with through traditional cutting processes, and is particularly suitable for the machining of complex parts such as molds and stampings. The principle is to etch and cut on the material surface by electrode discharge.

Application Example: FastPreci has custom-made high hardness steel molds for a mold manufacturer, using the EDM process to achieve fine mold cavity machining, ensuring the complex shape and durability of the mold.

Performance Characteristics: EDM processing is capable of handling materials with a hardness of HRC60 and above, and realizes micron-level fine machining.

4. CNC Laser Cutting Machine

CNC laser cutting machine uses high-energy laser beams to cut materials and is suitable for high-precision processing of a wide range of materials such as metals, plastics and composites, and is commonly used in the production of thin sheet metal parts.

Application example: FastPreci processed aluminum housings for an electronic components company, using the CNC laser cutting machine to achieve a complex design of vents and mounting holes that ensured the accuracy of each cut.

Processing Efficiency Data: The laser cutter we use is capable of cutting complex shapes in seconds, with a cutting accuracy of ±0.05mm.

Why choose FP’s CNC machining equipment?

FastPreci’s equipment not only comes in a wide range, but also utilizes the latest technological upgrades to ensure efficient and highly accurate machining. Our equipment is maintained and calibrated in strict compliance with industry standards to ensure that every process meets customer requirements. At the same time, our team of engineers has extensive experience in operating the equipment and is able to provide the optimal choice of equipment for different materials and projects.

CNC machining equipment is the foundation of FastPreci’s quality service. Whether your project requires high-precision milling, turning, or fine machining of specialized materials, we have the advanced equipment and professional team to meet your needs. We understand the uniqueness of each project, and therefore always maintain a rigorous approach to equipment technology and optimization to ensure the success of each project.