Characteristics of Composite Materials

Composite materials are material systems composed of two or more materials with different properties, and their main characteristics include:

- Lightweight and High Strength: Composites are often half the weight or less of traditional metal materials, but have similar or even higher strength. For example, the specific strength (strength/density ratio) of carbon fiber is much higher than that of steel, making it particularly suitable for scenarios where strength and light weight are required.

- Corrosion resistance: Polymer matrix composites, such as fiberglass composites, have excellent corrosion resistance for applications in harsh environments and high humidity conditions.

- Strong designability: composites can be customized with different combinations of materials to meet diverse design needs by customizing their physical and chemical properties, such as electrical conductivity, high temperature resistance, and thermal insulation.

Application areas of composites

Composite materials are widely used in the following fields due to their versatility and superior performance:

Aerospace: Carbon fiber composites are widely used in the aerospace industry, such as aircraft structural parts, satellite panels, etc., due to their lightweight and high strength characteristics. According to a Boeing data, carbon fiber composites account for more than 50% of its Boeing 787 models, greatly improving fuel efficiency and flight performance.

- Automotive industry: the application of composite materials in automotive manufacturing is becoming more and more widespread, especially in the field of electric vehicles, carbon fiber and glass fiber composites are used in the manufacture of body structural parts and interior parts, which not only reduces the weight of the vehicle, but also improves safety and energy efficiency. For example, the body of the BMW i3 electric car is mainly composed of carbon fiber composites, and its weight has been reduced by 30% compared with traditional materials.

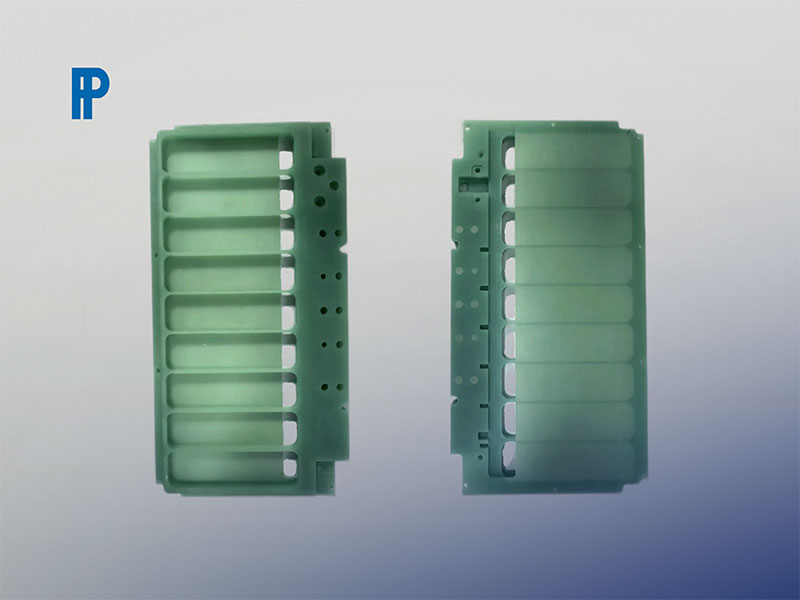

- Electronic and Medical Devices: Glass fiber composites are commonly used in the housings and circuit boards of electronic devices, with good electrical insulation and durability. In medical devices, the biocompatibility and lightweight nature of composites also make them widely used in implant and instrument manufacturing.

- Sports equipment: Carbon fiber composites are also widely used in the manufacture of high-end sports equipment, such as bicycle frames, tennis rackets and golf clubs, where their lightweight and robust properties enhance performance.

Composites in CNC machining

During CNC machining, composites offer a number of advantages due to their unique properties:

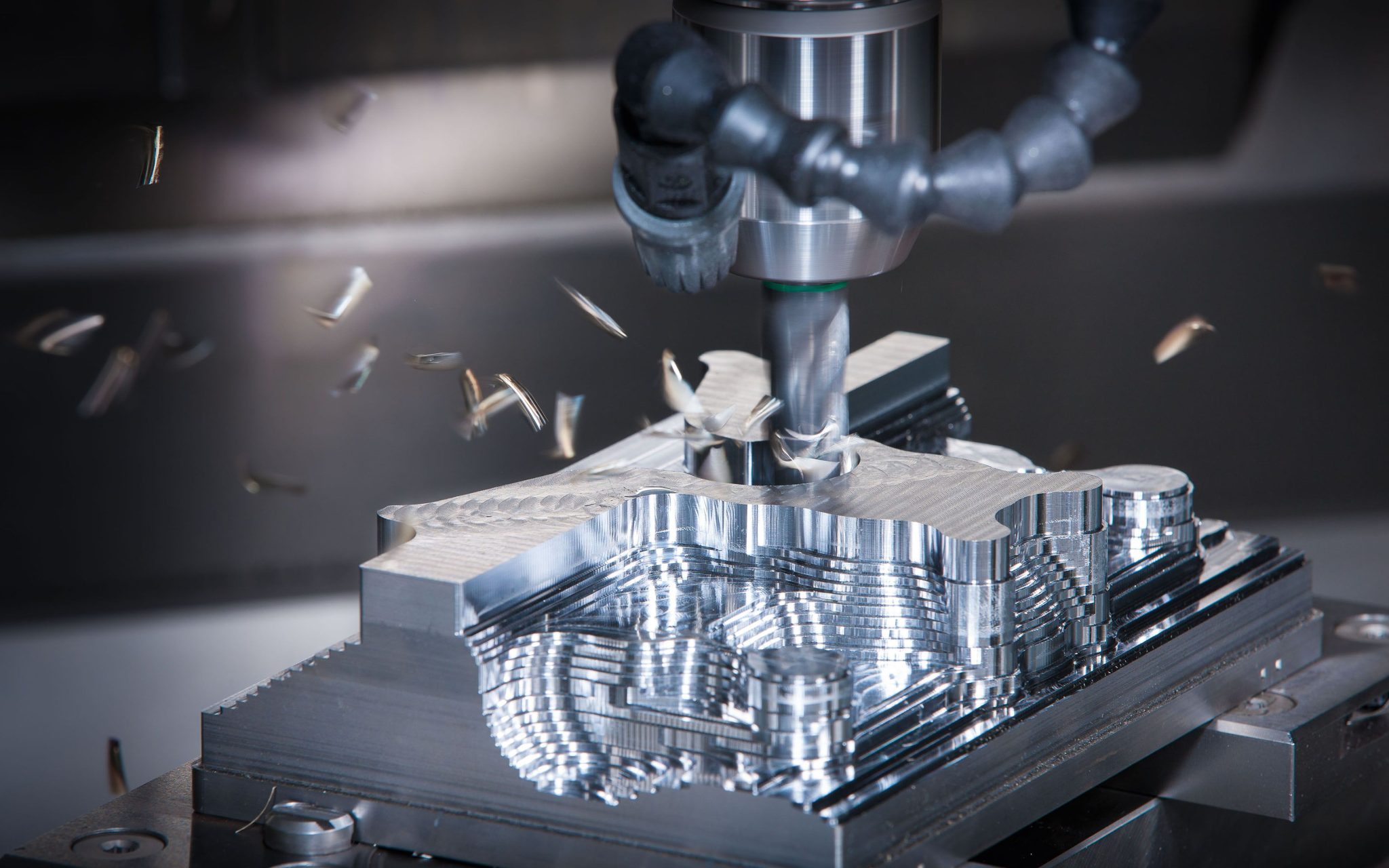

- High precision machining: the toughness and strength of composites allow them to maintain stable deformation control during CNC machining. fastPreci utilizes advanced CNC technology to ensure the machining of complex designs and fine details, especially in aerospace and electronics manufacturing where material precision is critical.

- High processing efficiency: The lower density of composites allows for more efficient material removal in CNC machining, reducing processing time and costs. For example, the ease of cutting of carbon fiber composites demonstrates significant time and cost advantages in high-volume production.

- Machining Challenges: Despite the many benefits of composites, there are also challenges in machining them, especially during chipping and heat treatment, where delamination can occur between layers of material. fastPreci avoids this problem by precisely controlling cutting parameters and optimizing tool selection when machining composites, ensuring the overall performance of the material.

Composites are widely used in CNC machining in a wide range of industries due to their light weight, high strength and corrosion resistance, and FastPreci’s extensive machining experience and know-how allows us to provide customized composite solutions to meet a wide range of needs, from aerospace to electronic devices. Regardless of the size of the project, our efficient and precise machining process ensures that every product meets the most exacting standards.

Choose FastPreci to drive innovation in your projects and bring more efficient and reliable material solutions to your products.