In the era of intelligent manufacturing, CNC milling is increasingly becoming the core of precision machining with its advantages of high precision, high efficiency and automation. Advanced equipment and optimized processes improve machining quality and efficiency.

In this article, we will analyze the principle of CNC milling, machine tool types, process flow, tool and material selection and digitalization trends for mechanical engineers and manufacturing personnel to provide reference.

CNC Milling Basic Concepts

1 Definition of CNC Milling

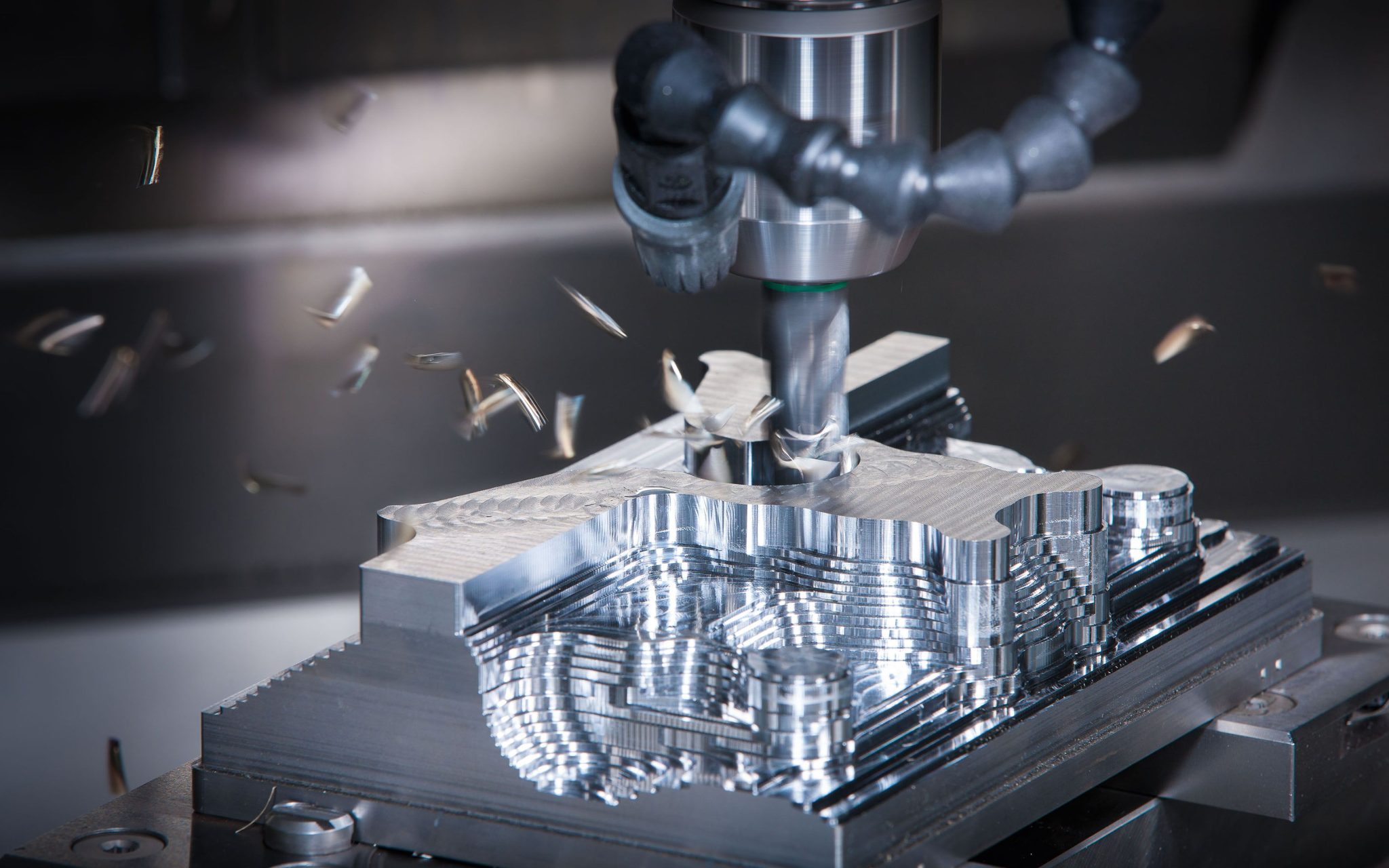

CNC milling (Computer Numerical Control Milling) is to control the machine tool through a computer program, cutting the workpiece continuously with a tool, adding excess material layer by layer to form the desired geometry. Since the 1970s, CNC milling technology has continued to develop, with increased levels of precision and automation, widely covering aerospace, automotive manufacturing, medical devices and other fields.

2 Working Principle of CNC Milling

CNC milling controls the machine tool in multiple axes through pre-written G-code, moving according to a set trajectory so as to carry out cutting machining. Its core technologies include:

- ●CNC system: High-performance CNC system analyzes program instructions in real time and precisely controls tool movement.

- ●Tool path planning:Use CAM software to simulate and optimize machining paths to ensure efficient and high-precision cutting.

- ●Multi-axis linkage:Add rotary axes to machine complex surfaces and geometries, reducing the number of clamping times and errors.

3 Types of CNC Milling

- 3-axis milling: using three linear axes X, Y, Z, suitable for plane or simple parts machining, simple operation, low cost.

- 4-axis milling:adding a rotary axis (e.g. A-axis) on the basis of three-axis, suitable for machining parts with curvature or rotational symmetry, and reducing the number of clamping times.

- 5-axis milling:adding two rotary axes to realize multi-angle linkage, suitable for machining complex curved surfaces and high-precision parts.

- Specialized machines:including vertical milling, horizontal milling, gantry milling, etc., which are suitable for machining workpieces of different sizes and shapes with stronger cutting stability.

CNC Milling Process

1 Programming for CNC Milling

The CNC milling process starts with accurate design. Engineers use CAD software to create a three-dimensional model of the part, which is then converted into toolpaths and G-code by a CAM system. Seamless data transfer and standardized processing not only shortens the production cycle, but also ensures that each cutting path is optimized through rigorous simulation, reducing idle time and machining errors.

2 Clamping for CNC Milling

In CNC milling, clamping is the key to ensuring the stability of the workpiece. Special fixtures must be designed according to the characteristics of the parts to prevent small displacements during machining. The use of a high-precision tool setting device to determine the zero point position of the tool and the workpiece to reduce the clamping error lays the foundation for high-precision cutting.

3 CNC milling cutting process with real-time monitoring.

In CNC milling, parameters such as high-speed cutting, feed rate, depth of cut, etc. must be set precisely according to the material and tool characteristics to ensure stable machining quality. The following are common cutting parameters for various materials:

| Material | Spindle speed(rpm) | Feed rate(mm/min) | Cutting depth(mm) | Overview |

| aluminum (6061, 7075) | 10,000-30,000 | 1000 – 5000 | 0.5 – 3.0 | Carbide tools can be used for high-speed milling |

| aluminum alloy (Ti-6Al-4V) | 2000 – 8000 | 200 – 800 | 0.2 – 1.0 | Low speed and high heat treatment, recommended tools (e.g. TiAlN) |

| stainless steels (304, 316L) | 3000 – 12,000 | 500 – 1500 | 0.3 – 1.5 | High cutting forces require optimized coolant supply to prevent spindle wear |

| copper alloy(C360, C110) | 8000 – 25,000 | 800 – 4000 | 0.5 – 2.0 | Good conductivity for high feed rates |

| engineering plastics (POM, PEEK) | 5000 – 20,000 | 2000 – 6000 | 1.0 – 5.0 | Low cutting forces to prevent deformation due to overheating |

Note: Specific parameters must be optimized and adjusted according to the spindle diameter, cooling method and machine spindle, and it is recommended to simulate in CAM software to ensure the best machining results.

In addition, we apply real-time monitoring system in production, by collecting sensor spindle growth rate, tool spindle speed, temperature and vibration to improve the data, and combined with big data analysis for dynamic adjustment, effective machining accuracy, extend tool life, to ensure production stability.

4 CNC Milling Quality Control

The final stage of precision machining is rigorous quality inspection. High-precision dimensional inspection equipment such as CMMs and laser scanners are used to comprehensively inspect workpiece dimensions, geometry and surface roughness. Inspection data is compared to design parameters to create a closed-loop feedback loop that provides the basis for subsequent process optimization. Data traceability is implemented throughout the process, from raw materials entering the factory to finished products leaving the warehouse, each process is recorded in detail to ensure that product quality ultimately meets international standards.

CNC Milling Tools and Materials

1 Material Properties and Cutting Strategies for CNC Milling

Metals and engineering plastics are two materials commonly used in CNC precision machining. Different materials require different cutting strategies:

- Aluminum alloy: good thermal conductivity, strong cutting, can be used for high-speed cutting.

- Titanium alloy: It is usually machined at low speeds and low depths of cut, in conjunction with efficient cooling measures, due to poor thermal conductivity and machining difficulty.

- Composites:You need special tools to prevent the material from delamination or fragmentation. ·

We have collected a lot of test data. This has allowed us to create a detailed library of processing parameters for endpoint materials. This library enables accurate and stable production.

2 Choosing the right tools for CNC milling

Tooling is an essential part of CNC precision machining. The material, structure, and coating process of the tooling directly affect the cutting effect:

- Material Selection: Common tool materials include high-speed steel, carbide and ceramic. Each has unique advantages – some excel in wear resistance, while others are better at withstanding extreme temperatures.

- Coating Technology:Modern coatings (like TiN and TiAlN) can reduce friction and control cutting temperatures. This makes tools last longer.

- Tool geometry design: Optimizing cutting, front and back angles improves cutting conditions, chip evacuation and surface finish.

We are always bringing you the latest and greatest in advanced tool technology. We also offer custom tooling solutions for all kinds of machining needs. This way, every time you cut something, you get the results you want.

Digitalization and Intelligent Manufacturing for CNC Milling

1 Digital Twin and Virtual Simulation

With the global adoption of Industry 4.0, digital twin technology is transforming traditional machining. By creating a virtual replica of the actual process, engineers can simulate toolpaths, cutting parameters and vibrations before machining, identifying risks and optimizing designs in advance.

We are pioneering the application of digital twin technology to CNC milling process planning, improving process control and predictability and delivering more reliable custom machining services.

2 The Internet of Things (IoT), Big Data, and Intelligent Monitoring.

Modern CNC machining is more than just mechanical cutting, It’s also a data-driven, intelligent control integrated system.

By connecting machine tools, sensors, and testing equipment, we gather real-time data like temperature, vibration, and tool wear. Using big data and AI algorithms, we dynamically adjust processes to optimize CNC milling.

We’re continuously researching and developing innovative methods to ensure smooth machine operation and the production of precise parts.

3 Green Manufacturing and Sustainable Development

As global environmental regulations tighten, green manufacturing is essential to remaining competitive. By optimizing our processes, reducing waste and recycling cutting fluids, we reduce costs while protecting the environment.

We prioritize green manufacturing to ensure precise machining, efficient use of resources and environmental protection to provide our customers with environmentally friendly and efficient machining solutions.

Implications for Mechanical Engineers

In the face of rapid technological advancements and changing market demands, mechanical engineers must master traditional machining principles while also embracing digitalization, intelligent manufacturing, and interdisciplinary innovation. The following insights are crucial and warrant deeper focus:

- Continuous learning and technology innovation

Continually updating knowledge and focusing on cutting-edge technologies such as digital twins, artificial intelligence, and the Internet of Things are essential to driving continuous breakthroughs and optimizing processes.

- Data-driven refined management

By using digital monitoring throughout the process and analyzing large amounts of data, real-time dynamic adjustments ensure accuracy and stability at every stage, ultimately improving product quality and production efficiency.

- Interdisciplinary collaboration and innovative integration

Manufacturing development now extends beyond mechanical engineering to include materials science, computer science, and automation control. Engineers should actively collaborate across disciplines to drive technological innovation.

- Green manufacturing and social responsibility

In the pursuit of high efficiency and precision, while emphasizing resource conservation and environmental protection, green manufacturing aligns with sustainable development goals and serves as a key indicator of future corporate competitiveness.

Conclusion:

CNC milling technology is driving the manufacturing industry toward digitalization and intelligence. FastPreci focuses on custom precision parts machining, providing high-precision machining services through advanced equipment, optimized processes and digital monitoring. We believe that technological innovation is not only based on equipment upgrades, but also on improved process flow and data management.

We welcome machine builders and industry experts to discuss the future of CNC milling technology with us. Your input is very important to us. We hope this article can provide you with useful information, and together we can welcome the new era of smart manufacturing and green manufacturing!

Thank you for reading, and please feel free to leave a comment or contact us for communication. Stay tuned to FastPreci for more updates on CNC milling and custom precision machining technologies.