Custom Composite CNC Machining

FastPreci offers composite materials such as carbon fiber, fiberglass and polymers. Lightweight, strong and corrosion resistant, composites are ideal for industries such as aerospace, automotive and electronics.

Commonly Used Composite Materials

Carbon fiber is a lightweight, high-strength composite material widely used in aerospace, automotive and electronics. It has high precision, corrosion resistance, thermal stability and good strength and rigidity, and is particularly suitable for precision parts, lightweight design and applications in high-temperature environments.

| Model | Density (g/cm³) | Tensile Strength | Tensile Modulus | Thermal Stability | Conductivity |

| T300 | 1.76 | 3500 | 230 | Medium | High |

| T700 | 1.8 | 4900 | 240 | High | High |

| T800 | 1.81 | 5880 | 294 | High | High |

| M40J | 1.78 | 4120 | 377 | High | Medium |

| IM7 | 1.8 | 5700 | 276 | High | Medium |

| HM | 1.85 | 2400 | 540 | High | Low |

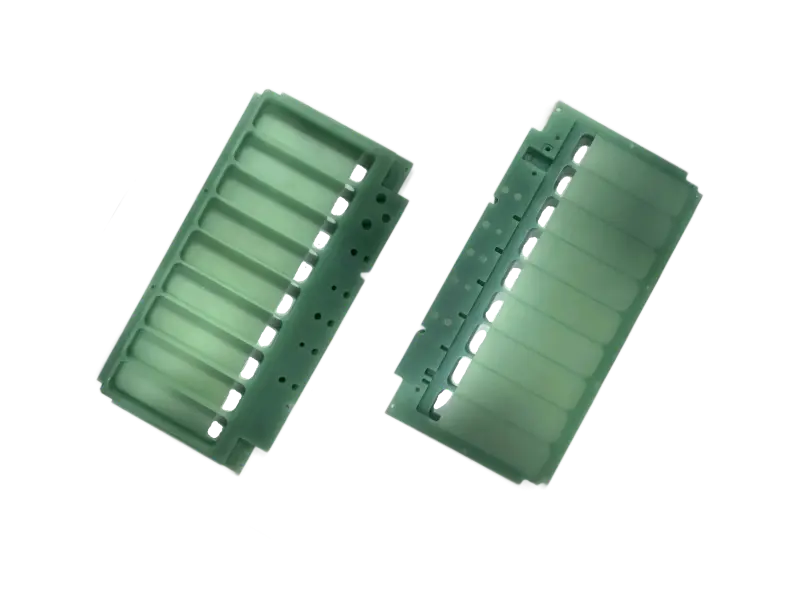

Glass fiber (GFRP) is a high-strength, lightweight composite material with excellent corrosion resistance and electrical insulation, widely used in CNC machining. It is suitable for the manufacture of chemically resistant parts, electrical insulators and lightweight structural components. Due to its good hardness, toughness and processability, fiberglass is commonly used to produce structural parts and housings, especially with the support of reinforcing materials such as epoxy and phenolic resins, which provide higher impact resistance and thermal stability.

| Model | Density (g/cm³) | Tensile Strength (MPa) | Thermal Stability | Hardness | Insulation | Corrosion resistance |

| G10 | 1.80-1.90 | 150-220 | 130-180°C | High | Excellent | Strong |

| FR4 | 1.80-1.90 | 100-250 | 120-140°C | Medium | Good | Medium |

| G11 | 1.80-1.90 | 200-250 | 150-180°C | High | Excellent | Strong |

| CEM-1 | 1.80-1.90 | 100-150 | 100-130°C | Medium | Average | Medium |

| CEM-3 | 1.80-1.90 | 120-200 | 110-130°C | Medium | Good | Medium |

Polymer Matrix Composites (PMCs) are lightweight, high-strength materials made from polymer matrices, often reinforced with fibers like carbon, glass, or Kevlar. Known for their excellent corrosion resistance, thermal stability, and mechanical strength, PMCs are ideal for manufacturing high-performance components. Their low density reduces part weight, while maintaining structural stability and impact resistance, making them popular in aerospace, automotive, sports, and medical industries.

| Material Type | Density (g/cm³) Tensile | Strength (MPa) | Modulus of Elasticity (GPa) | Heat resistance |

| Carbon Fiber Reinforced Polymer (CFRP) | 1.5-2.0 | ~3500 | 230-450 | High |

| Glass Fiber Reinforced Polymer (GFRP) | ~1.9 | ~1000 | 70 | High |

| Kevlar (Aramid) Reinforced Polymer (AFRP) | ~1.4 | ~3000 | 130 | Medium |

| Natural Fiber Reinforced Composites | 1.0-1.5 | 100-300 | 10-20 | Low |

| High Performance Polymer Matrix Composites | 1.3-1.6 | 200-400 | 20-50 | High |

- Multiple material options for precision manufacturing needs

- Light weight, high strength, corrosion resistance, enhance product reliability

- Innovative composite processing to push the limits of your design

- Strict quality control to ensure excellent quality