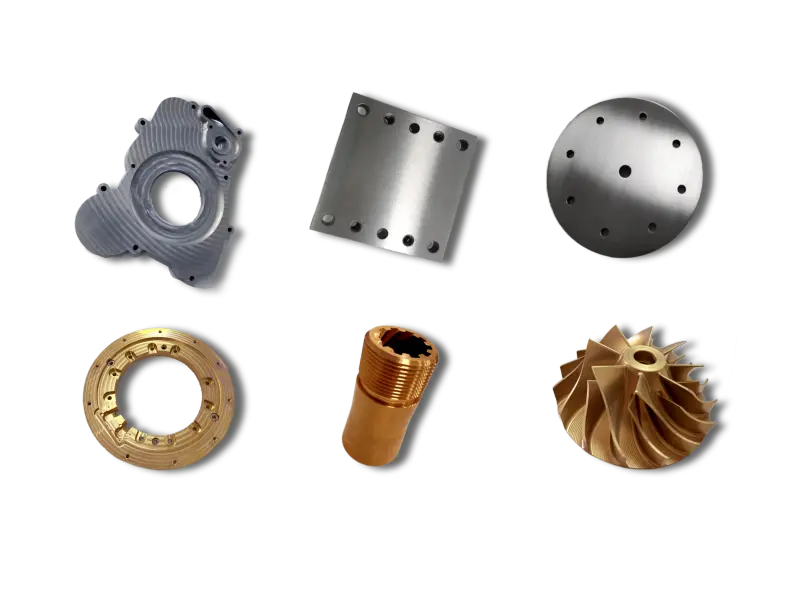

Custom Metal CNC Machining

FastPreci provides a wide selection of premium metal materials, including aluminum, steel, stainless steel, brass, copper, and specialized alloys. Meeting the needs of different projects for strength, corrosion resistance, and specialized physical properties, suitable for both precision components and large structural parts.

Commonly Used Metal Materials

Aluminum is widely used in CNC machining for its light weight, high strength and corrosion resistance. It is suitable for precision machining and complex designs, and is commonly used in aerospace, automotive, electronics and medical devices. The main models are 6061, 7075, 2024, etc.

| Model | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) | Thermal Conductivity (W/m-K) | Thermal Expansion (µm/m°C) |

| 6061 | 2.7 | 310-350 | 275-310 | 10-17 | 95 | 167 | 23.6 |

| 7075 | 2.81 | 510-570 | 430-480 | 5-11 | 150 | 130 | 23.5 |

| 2024 | 2.78 | 420-470 | 290-330 | 10-15 | 120 | 138 | 23.2 |

| 5052 | 2.68 | 228-260 | 193-210 | 12-20 | 60 | 138 | 23.8 |

| 5083 | 2.66 | 275-350 | 125-135 | 15-20 | 75 | 117 | 24.2 |

| 6063 | 2.7 | 190-240 | 150-215 | 8-12 | 70 | 200 | 23.5 |

Steel is widely used in CNC machining for its high strength, wear resistance and good machinability, suitable for tools, machine parts and structural supports in high stress environments. Commonly used models are such as 1018, 1045, 4140, etc.

| Model | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) | Thermal Conductivity (W/m-K) | Thermal Expansion (µm/m°C) |

| 1045 (carbon steel) | 7.85 | 570-700 | 370-470 | 16-20 | 170 | 46 | 11.8 |

| A36 (structural steel) | 7.85 | 400-550 | 250-350 | 20-25 | 130 | 50 | 11.8 |

| 4140 (Alloy Steel) | 7.85 | 680-850 | 450-635 | 20-30 | 207 | 41 | 11.5 |

| 4340 (Alloy Steel) | 7.85 | 750-930 | 635-760 | 12-20 | 241 | 45 | 11.6 |

| SS304 (Stainless Steel) | 7.93 | 520-720 | 210-310 | 40-50 | 160 | 16 | 17.3 |

| SS316 (Stainless Steel) | 7.98 | 520-720 | 210-290 | 35-50 | 150 | 16 | 16.5 |

| ToolSteel | 7.85 | 900-1200 | 500-1000 | 5-10 | 400-700 | 30 | 11 |

Stainless steel is widely used in CNC machining for medical, food processing, automotive parts and building structures due to its excellent corrosion resistance, strength, heat resistance and machinability. Commonly used types such as 304, 316 and 17-4PH.

| Model | Density | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) | Thermal Conductivity (W/m-K) | Thermal Expansion (µm/m°C) |

| SS304 | 7.93 | 520-720 | 210-310 | 40-50 | 160 | 16 | 17.3 |

| SS316 | 7.98 | 520-720 | 210-290 | 35-50 | 150 | 16 | 16.5 |

| SS310 | 7.9 | 520-750 | 210-310 | 40-45 | 170 | 20 | 17 |

| SS430 | 7.7 | 450-600 | 200-300 | 12-22 | 160 | 24 | 11 |

| SS17-4PH | 7.75 | 930-1100 | 600-750 | 10-12 | 300 | 16 | 12.8 |

| SS2205(Duplex) | 7.8 | 650-850 | 450-600 | 25-35 | 250 | 15 | 16.5 |

| SS446 | 7.8 | 450-600 | 200-300 | 15-25 | 200 | 20 | 14.5 |

Brass is often used in CNC machining to make highly corrosion-resistant, electrically and thermally conductive parts, such as plumbing fittings, electronic connectors and decorative parts. Its soft texture, anti-bacterial and wear-resistant, easy to process complex structures, and the finished product has an elegant golden appearance. Commonly used models include C360, C260 and C385.

| Model | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) | Thermal Conductivity (W/m-K) | Thermal Expansion (µm/m°C) |

| C36000(Free-CuttingBrass) | 8.55 | 550-700 | 200-300 | 20-35 | 60 | 120 | 19.0 |

| C37700(CastingBrass) | 8.5 | 350-500 | 150-250 | 25-40 | 90 | 110 | 20.0 |

| C46400(NavalBrass) | 8.50 | 510-690 | 230-300 | 30-40 | 110 | 90 | 20.5 |

| C22000(YellowBrass) | 8.50 | 310-450 | 120-200 | 30-40 | 75 | 120 | 21.0 |

| C26000(MuntzMetal) | 8.55 | 420-600 | 170-250 | 30-40 | 85 | 120 | 21.2 |

| C90200(RedBrass) | 8.75 | 450-550 | 150-250 | 15-30 | 110 | 90 | 21.5 |

Bronze is widely used in CNC machining for marine fittings, bearings, gears and pumps and valves due to its excellent corrosion and wear resistance and high hardness properties. Its excellent anti-friction properties make it suitable for high loads and friction environments. Common types include C932, C954, C863, etc.

| Model | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) | Thermal Conductivity (W/m-K) | Thermal Expansion (µm/m°C) |

| AluminumBronze,C95400 | 7.6-7.8 | 620-800 | 250-400 | 10-25 | 150 | 85 | 18.5 |

| PhosphorBronze,C51000 | 8.9 | 500-600 | 200-300 | 25-30 | 120 | 70 | 19.0 |

| TinBronze,C90700 | 8.8 | 400-600 | 150-250 | 15-25 | 100 | 60 | 19.5 |

| LeadedBronze,C93200 | 8.5 | 400-500 | 200-300 | 20-30 | 90 | 70 | 20.0 |

| BismuthBronze,C63000 | 8.7 | 500-700 | 250-350 | 15-30 | 120 | 80 | 20.2 |

Copper (pure copper) is widely used in electrical and electronic components, radiators, piping systems and other fields due to its excellent electrical and thermal conductivity and corrosion resistance. Copper is soft and easy to process, with high surface finish, suitable for high-precision machining. Commonly used models such as C110, C101 and so on.

| Model | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) | Thermal Conductivity (W/m-K) | Thermal Expansion (µm/m°C) |

| C11000 (electrolytic copper) | 8.92 | 210-250 | 50-110 | 40-50 | 35-50 | 398 | 16.5 |

| C10200 (Oxygen-free copper) | 8.96 | 210-250 | 55-110 | 40-50 | 30-45 | 390 | 16.7 |

| C12000 (Copper Alloy) | 8.96 | 250-350 | 80-150 | 40-60 | 40-55 | 380 | 16.3 |

| C14500 (Phosphorus Copper) | 8.92 | 250-350 | 100-200 | 40-50 | 45-55 | 370 | 16.1 |

| C17500 (Beryllium Copper) | 8.25 | 900-1100 | 600-800 | 5-15 | 180-230 | 120 | 16.2 |

Titanium is widely used in CNC machining in aerospace, medical implants, and automotive high-performance parts due to its high strength, light weight, corrosion and heat resistant properties. Its high biocompatibility and strength-to-weight ratio make it particularly suitable for demanding applications, and commonly available models are Ti-6Al-4V (Grade 5) and Grade 2.

| Model | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) | Thermal Conductivity (W/m-K) | Thermal Expansion (µm/m°C) |

| Grade2(CommerciallyPureTitanium) | 4.51 | 370-550 | 230-300 | 20-30 | 160-200 | 21.9 | 8.5 |

| Grade3 | 4.50 | 550-620 | 480-560 | 20-25 | 210-250 | 21.7 | 8.5 |

| Grade5(Ti-6Al-4V) | 4.43 | 900-1100 | 800-1000 | 10-15 | 330-350 | 7.6 | 8.6 |

| Grade5(Ti-6Al-4VELI)(ExtraLowInterstitial) | 4.43 | 1000-1200 | 900-1100 | 15-18 | 340-360 | 7.6 | 8.6 |

| Grade23(Ti-6Al-4VELI) | 4.43 | 860-1000 | 790-950 | 15-20 | 350-375 | 7.6 | 8.6 |

Magnesium metal in CNC machining is widely used in aerospace, automotive and electronic housings where weight reduction is in high demand due to its ultra-light mass, high strength and vibration damping properties. Magnesium alloys are easy to machine and are suitable for complex structures and high-precision parts, with common models such as AZ31, AZ91 and WE43.

| Model | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) | Thermal Conductivity (W/m-K) | Thermal Expansion (µm/m°C) |

| AZ31B | 1.77 | 230-260 | 170-200 | 15-20 | 60-80 | 156 | 26.7 |

| AZ61A | 1.78 | 260-280 | 210-240 | 15-20 | 70-100 | 156 | 27.1 |

| ZK60A | 1.81 | 320-350 | 270-300 | 20-25 | 90-120 | 156 | 27.5 |

| WE43 | 1.80 | 380-400 | 310-350 | 18-22 | 100-130 | 130 | 26.0 |

| Elektron21 | 1.78 | 250-300 | 190-220 | 20-25 | 80-100 | 130 | 26.5 |

Zinc metal is widely used in CNC machining in the electronics, automotive and construction industries due to its excellent castability, corrosion resistance and economy. Zinc alloy has good impact resistance and dimensional stability, which makes it suitable for complex parts and thin-walled structures, and the commonly used models are Zamak3, Zamak5 and ZA-8, etc.

| Model | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) | Thermal Conductivity (W/m-K) | Thermal Expansion (µm/m°C) |

| Zinc3(Z3) | 6.7 | 220-270 | 170-220 | 5-10 | 40-70 | 120 | 25 |

| Zinc5(Z5) | 6.9 | 250-280 | 190-220 | 10-15 | 50-90 | 120 | 25.2 |

| Zinc8(Z8) | 6.8 | 270-300 | 220-250 | 15-20 | 60-100 | 120 | 25.3 |

| ZA-12 | 7.1 | 380-420 | 290-330 | 5-10 | 85-120 | 130 | 25.6 |

| ZA-27 | 7.2 | 420-460 | 330-370 | 6-12 | 100-140 | 130 | 25.8 |

- Multiple metal options to meet diverse processing needs

- High strength and corrosion resistance for reliable components

- Customized solutions to enhance product competitiveness

- Rapid delivery to accelerate the project process